Products We Provide

-

Screw Conveyor for Sale

-

Derrick Desilter Cones Replacement

-

Mud Cleaner for Solids Control System

-

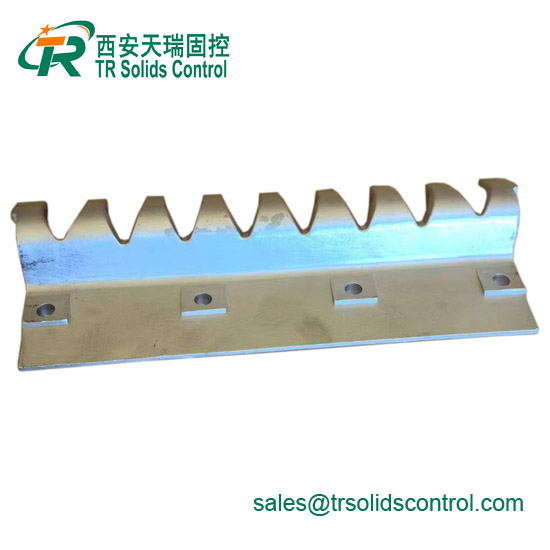

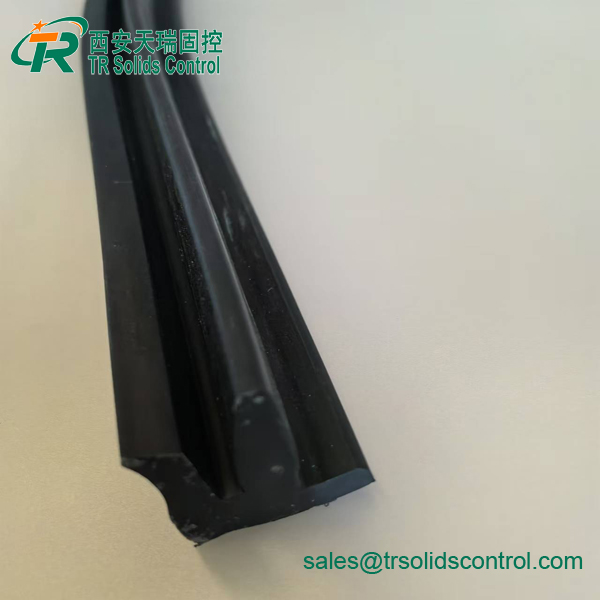

Tensioning Side finger for Derrick Shaker Screen

-

Fixed Side Fingers for Derrick Shakers

-

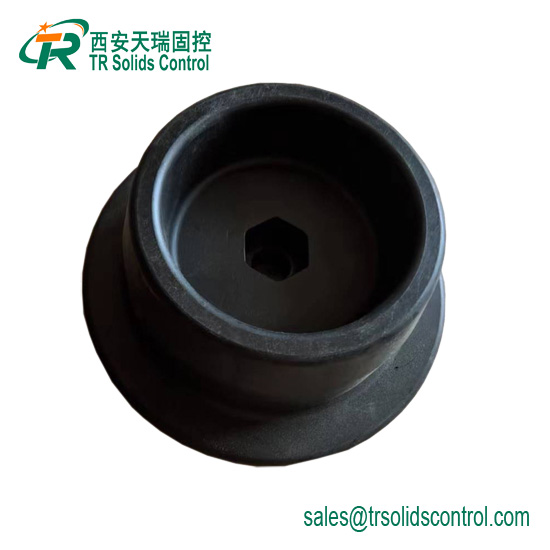

BM6K80290 SPRING SPOOL PLASTIC for Mongoose Shaker

-

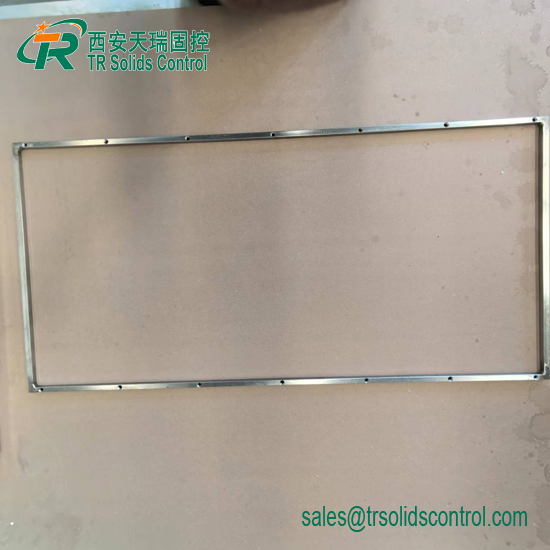

9671640 Screen Frame Weldment

-

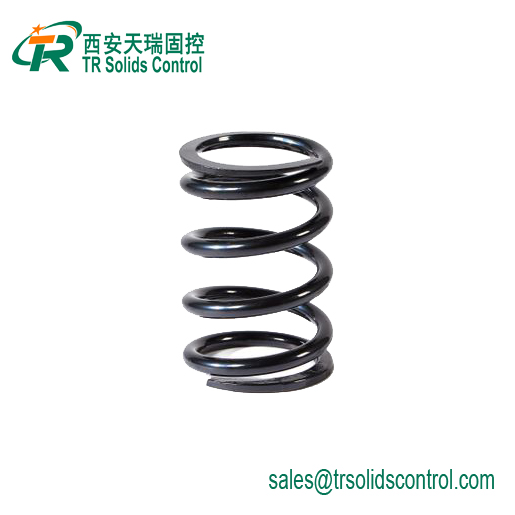

SWACO Spring Coil 9360007

-

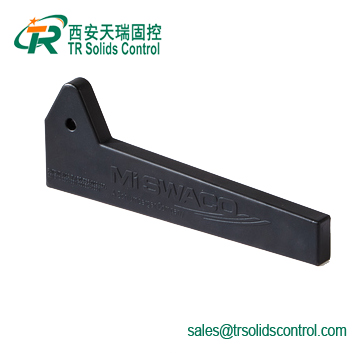

Mongoose Wedge – MONGOOSE Screen Clamping

-

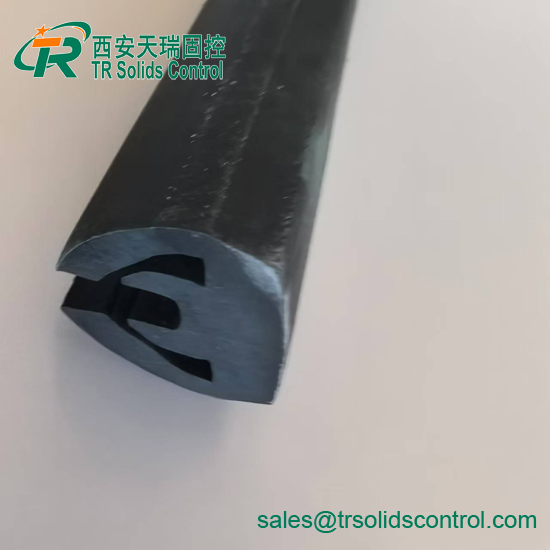

16848-01-001 Side Support Rubber

-

Buldhead Protector Double

-

Three Phase Separator

-

Mud Cooling System

-

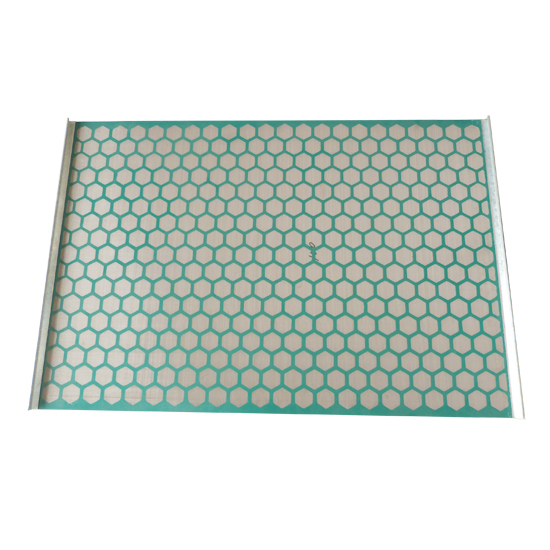

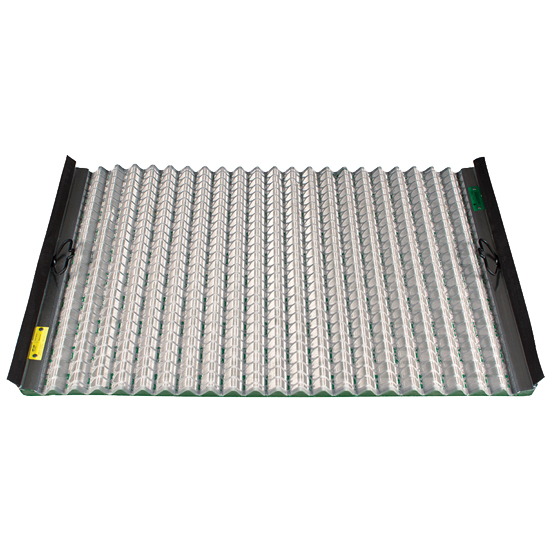

Mongoose Shaker Screen

-

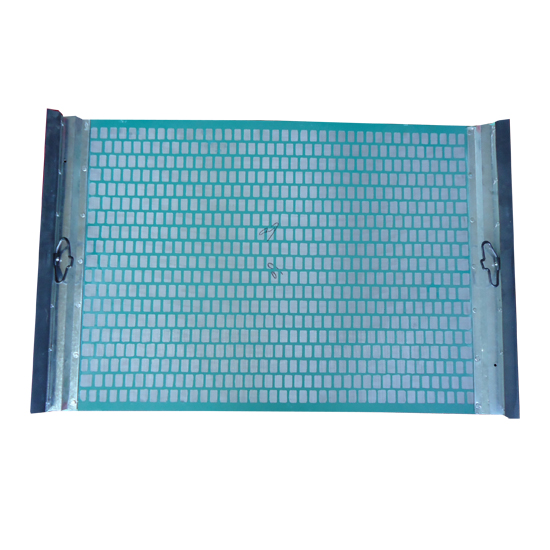

FLC2000 Flat Shaker Screen

-

FLC500 Flat Shaker Screen

-

FLC500 PMD Shaker Screen

-

Mud Recycling System for Drilling

-

Venturi Mud Hopper

-

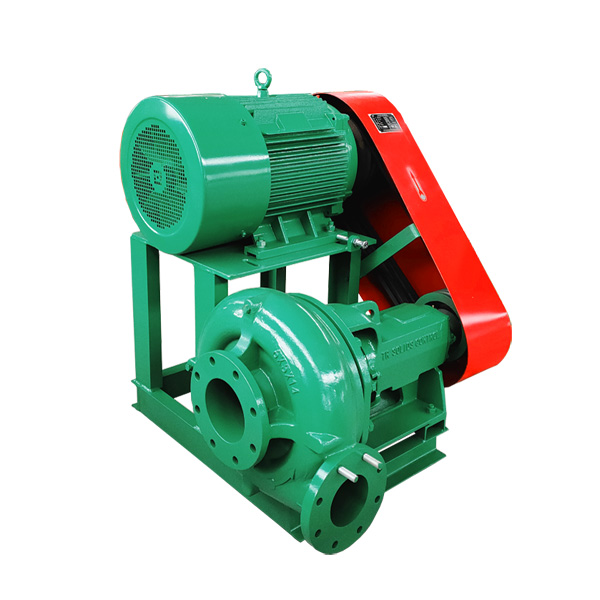

Mud Shear Pump

Automated Production & Strict Quality Control

-

Vacuum Degasser Welding

-

Vibration Strength Test

-

Desilter Cyclone Installation

-

Mud Shale Shaker Welding

-

Drilling Shale Shaker Welding

-

Mud Tank Produce

-

-

-

-

CNC Lathe

-

CNC Lathe

-

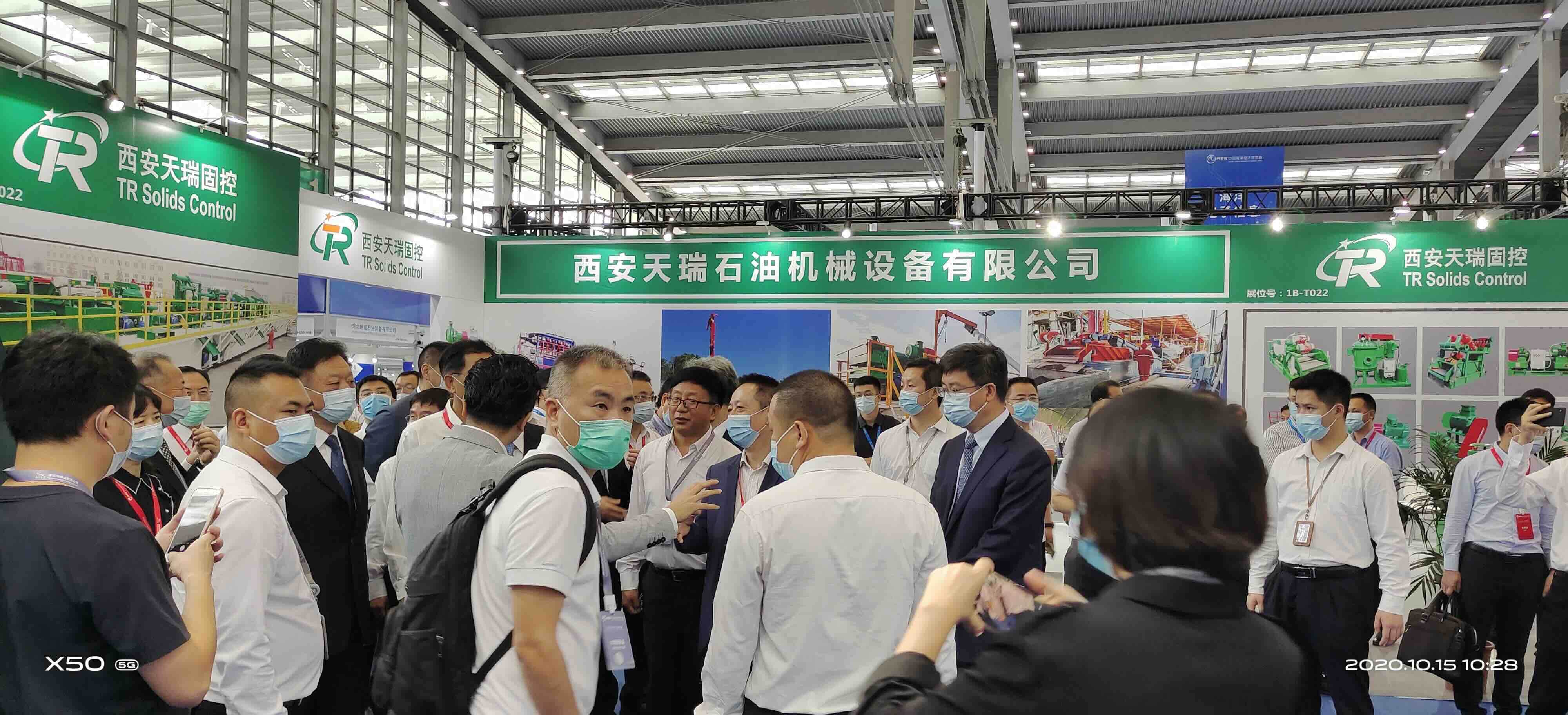

about us

Xi`an Tian Rui Petroleum Machinery Equipment Co., Ltd

TR focuses on the manufacture of solid-liquid separation equipment, and is an API certified manufacturer integrating research and development, production, sales and technical services. We have provided solid-liquid separation solutions or equipment to customers in more than 60 regions. Since its establishment in 2010, with years of technical accumulation and manufacturing experience, TR and Xi 'an Shiyou University have reached a strategic cooperation, started the research and development of solid-liquid separation equipment, solved a number of customer technical problems, has obtained and is applying for a number of patents, and passed the American Petroleum Institute API and China IS09001 quality certification.

MORE

- 2010

Established

- 200+

The company has more than 200 employees

- 5000

Registered capital of 50 million

- 820+

More than 820 products have been installed

CERTIFICATE OF HONOR

News

-

The Centrifugal Sand Pump Successfully Completed the Factory Test

2026.01.22

TR Solids Control successfully completed the factory test for a batch of high-end centrifugal sand pumps customized for foreign customers. Centrifugal Sand Pumps are one of the main equipment in solids control systems. -

Mission Centrifugal Pump for Jet Mixer

2026.01.07

The centrifugal pump and jet mixers produced by TR Solids Control are applied in the drilling of CNOOC. -

Mud Shale Shaker for Pakistan Drilling

2025.12.21

When it comes to drilling operations, the efficiency and effectiveness of the equipment used play a crucial role. One such essential equipment is the mud shale shaker. Drilling shale shaker is a device that uses vibrating screens to separate solids from drilling fluid.This separa... -

TR successfully Sent Mud Shakers To Overseas Drilling Sites

2025.12.21

TR Solids Control, a leading provider of solid control equipment for drilling operations, has recently announced that they have successfully sent 8 sets of Mud Shakers to an overseas drilling site. These vibrating screens are considered to be the primary screening equipment for d...