In the oil and gas industry, drilling operations require complex and highly specialized equipment to maintain efficiency, reduce downtime, and ensure safety. One of the essential components of this machinery is the mud shear pump. Mud shear pumps play a critical role in optimizing the performance of drilling fluids, which are essential for lubricating the drill bit, stabilizing the borehole, and transporting cuttings to the surface. In this article, we will explore the technology behind mud shear pumps, how they work, and the benefits they offer to oil and gas drilling operations.

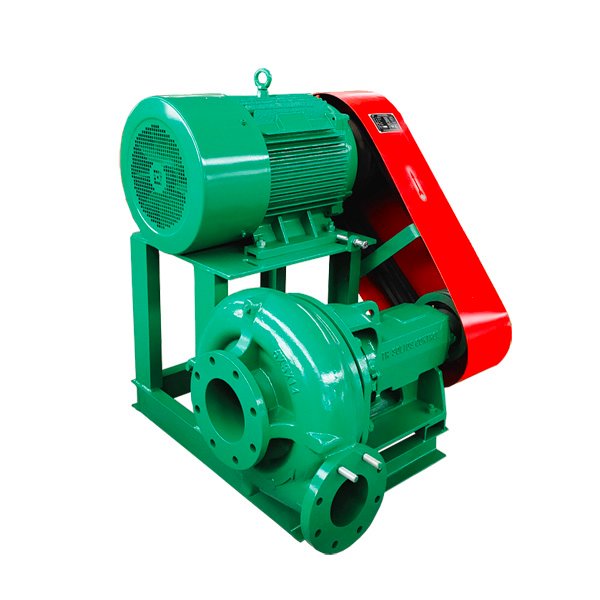

Mud shear pumps are designed to modify the viscosity and shear characteristics of drilling mud. Drilling mud, a mixture of water, clays, chemicals, and additives, serves multiple functions during the drilling process. The mud helps cool and lubricate the drill bit, prevent wellbore instability, and carry rock cuttings to the surface. Mud shear pumps are specialized machines that enhance the flow properties of this mud by applying high shear forces, which allow the fluid to perform better under various conditions.

These pumps are engineered to deliver high shear forces that break up clumps, remove aggregates, and ensure a smooth flow of the drilling fluid. As the fluid passes through the pump, its properties are optimized for better performance in the wellbore, which can help reduce downtime, enhance efficiency, and improve safety during the drilling process.

How Do Mud Shear Pumps Work?

Mud shear pumps are designed with impellers that generate significant shear forces. When the drilling fluid enters the pump, it is forced through the impeller system, which breaks up any clumps or aggregates in the fluid. This process ensures that the mud maintains its optimal viscosity, which is critical for effective circulation, cooling, and pressure control.

The high shear forces also help in mixing additives evenly, ensuring that they are properly distributed throughout the fluid. This is essential because inconsistencies in the mud can lead to inefficiencies, such as poor hole cleaning, excessive mud loss, or reduced control over the well.

Key Features of Mud Shear Pumps

Mud shear pumps are designed to meet the demanding requirements of the oil and gas industry. These pumps must operate efficiently, handle large volumes of fluid, and maintain a consistent performance under high pressures. Below are the main features of mud shear pumps:

| ميزة | وصف |

|---|---|

| High Shear Impellers | These specialized impellers generate the shear forces required to break down the mud and ensure optimal mixing. |

| Variable Speed Control | Allows the pump to adjust the shear rate, adapting to different types of mud and well conditions. |

| متانة | Constructed with corrosion-resistant materials to withstand harsh environments, ensuring a long service life. |

| كفاءة الطاقة | Designed to maximize energy efficiency, reducing operational costs while maintaining high performance. |

| تصميم مدمج | The small footprint of the pump allows it to be easily integrated into space-constrained drilling operations. |

The Role of Mud Shear Pumps in Drilling Operations

Mud shear pumps play a crucial role in improving the efficiency and safety of drilling operations. Here’s a breakdown of how they contribute to different stages of the drilling process:

1. Optimizing Mud Viscosity

The viscosity of drilling mud is a vital factor in ensuring efficient drilling. If the mud is too thick, it can create excessive pressure and slow down the drilling process. If it is too thin, it may not effectively carry cuttings to the surface, leading to poor hole cleaning and potential damage to the wellbore. Mud shear pumps help maintain the ideal viscosity by breaking down the aggregates and ensuring a smooth and consistent flow of the mud.

2. Improving Hole Cleaning

The efficient transportation of rock cuttings from the wellbore to the surface is critical for maintaining a clean and stable hole. Mud shear pumps help achieve better hole cleaning by ensuring that the drilling fluid remains in optimal condition. The high shear forces applied by the pump ensure that the mud is capable of suspending and transporting cuttings effectively, reducing the chances of a clogged or unstable hole.

3. Enhancing Drilling Speed

Efficient mud circulation is crucial for maintaining drilling speed. When the mud flows smoothly and maintains the right viscosity, the drill bit operates more efficiently, leading to faster drilling. By ensuring that the mud performs optimally under varying conditions, mud shear pumps can directly contribute to reduced drilling times and improved productivity.

4. Well Control and Safety

Mud shear pumps are also integral in maintaining well control. Properly mixed mud with the right properties helps stabilize the borehole and counterbalance the pressure from the formation. This reduces the likelihood of blowouts and other dangerous situations. The pump ensures that the mud stays consistent in viscosity and flow, preventing pressure anomalies that could lead to unsafe conditions.

Benefits of Using Mud Shear Pumps

Mud shear pumps provide numerous benefits to drilling operations, including enhanced efficiency, cost savings, and improved safety. Below are some of the key advantages:

| فائدة | وصف |

|---|---|

| تحسين تنظيف الثقب | Mud shear pumps ensure that the drilling fluid maintains the right properties to effectively remove cuttings, resulting in a cleaner, more stable hole. |

| Reduced Mud Consumption | By optimizing the mud’s performance, shear pumps help reduce the amount of drilling fluid required, saving on both material costs and operational downtime. |

| Faster Drilling Times | Efficient fluid circulation and optimal fluid properties contribute to faster drilling speeds and shorter operational timelines. |

| Better Well Control | By maintaining pressure control and stabilizing the wellbore, mud shear pumps enhance the overall safety of the drilling operation. |

| Lower Operational Costs | With reduced downtime, fewer maintenance needs, and optimized mud performance, shear pumps contribute to lower overall operational expenses. |

Common Challenges in Mud Shear Pump Operation

While mud shear pumps offer numerous advantages, they are not without their challenges. Some of the common issues include:

1. Cavitation

Cavitation occurs when air bubbles form in the pump due to low pressure. This can cause the pump to lose efficiency, leading to fluctuating performance and potential damage to the equipment. Proper pump selection and maintenance can help mitigate cavitation.

2. Wear and Tear

Mud shear pumps operate in harsh environments, and continuous use can lead to wear and tear on the impellers and other components. Regular maintenance and using corrosion-resistant materials can help extend the lifespan of the pump.

3. Inconsistent Fluid Properties

Mud shear pumps are designed to work with fluids of specific viscosities and properties. Variations in the mud composition can impact the performance of the pump. It’s essential to monitor and maintain the fluid properties to ensure optimal pump efficiency.

خاتمة

Mud shear pumps are indispensable in modern oil and gas drilling operations. These pumps ensure that drilling fluids remain at the correct viscosity and flow properties, which are essential for optimal drilling performance, well control, and safety. The technology behind mud shear pumps continues to evolve, offering improved efficiency, reduced operational costs, and enhanced safety for drilling teams. By maintaining optimal fluid performance, mud shear pumps contribute significantly to reducing downtime, improving hole cleaning, and ensuring faster drilling times.