A mud cooler system is designed to maintain the ideal temperature of the drilling fluid by removing excess heat generated during the drilling process. Drilling fluid plays a vital role in cooling the drill bit, lubricating the drilling string, and transporting cuttings from the borehole to the surface. However, as the fluid circulates, it can heat up, especially when the drilling operation involves high-speed rotations and increased friction.

El mud cooler system employs various methods of heat transfer, including air cooling, water cooling, or direct heat exchange to maintain the fluid’s temperature within the desired range. This ensures that the drilling fluid retains its optimal properties for effective lubrication and cooling, preventing excessive wear on drilling equipment and avoiding premature failure of the fluid itself.

1. Key Components of the Mud Cooler System

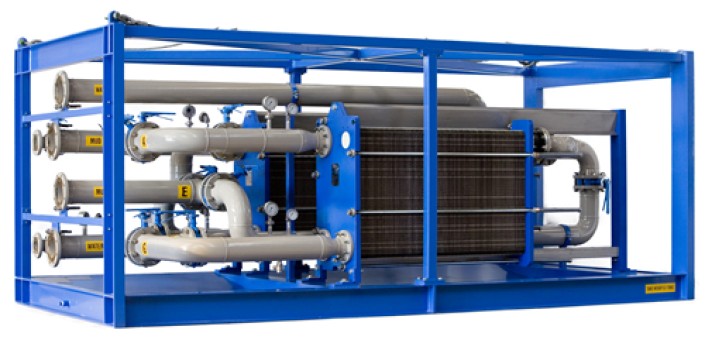

El mud cooler system typically consists of several components that work together to regulate the temperature of the drilling fluid. These include:

| Component | Function |

|---|---|

| Heat Exchanger | Transfers heat from the drilling fluid to a cooler medium (water or air). |

| Cooling Fans | Used in air-cooled systems to enhance the heat dissipation process. |

| Pumps | Circulates the drilling fluid through the heat exchanger. |

| Control Valves | Regulate the flow of drilling fluid and cooling medium. |

| Filters | Removes debris from the drilling fluid to prevent clogging. |

| Temperature Sensors | Monitor the temperature of the fluid to ensure it stays within the desired range. |

1.1. Heat Exchanger

El heat exchanger is the heart of the mud cooler system. It facilitates the heat transfer between the hot drilling fluid and the cooling medium, which can either be water or air. In air-cooled systems, the heat exchanger uses air to remove heat from the fluid, while in water-cooled systems, water is used as the cooling medium. The heat exchanger helps maintain the drilling fluid's viscosity and prevents it from becoming too thick or unstable due to high temperatures.

1.2. Cooling Fans (for Air-Cooled Systems)

For air-cooled mud cooler systems, cooling fans are critical components that blow ambient air across the heat exchanger to help expel heat from the drilling fluid. The fans increase the rate of heat dissipation, enhancing the system's cooling capacity. They are typically equipped with adjustable speed settings to ensure efficient operation under varying environmental conditions.

1.3. Pumps

Pumps are used to circulate the drilling fluid through the heat exchanger. In most cases, centrifugal pumps are employed because they provide steady and reliable fluid flow. These pumps also ensure that the fluid is circulated at a sufficient pressure and volume to facilitate heat transfer.

1.4. Control Valves

Control valves are used to regulate the flow of both the drilling fluid and the cooling medium (air or water). They allow operators to adjust the system's cooling capacity to match the requirements of the drilling operation. By controlling the flow rate of the cooling medium, the mud cooler system can efficiently regulate the temperature of the fluid.

1.5. Filters

Filters are used to remove any impurities or debris from the drilling fluid before it enters the mud cooler system. Contaminants can clog the system's components and reduce its efficiency. By ensuring the fluid is clean, filters contribute to the long-term durability of the mud cooler system.

1.6. Temperature Sensors

Temperature sensors are essential for monitoring the temperature of the drilling fluid and ensuring that it stays within the optimal range. These sensors relay data to a central control unit, which can adjust the system's parameters to maintain the correct temperature. If the fluid temperature rises above the safe limit, the system can automatically initiate cooling actions.

2. How Does the Mud Cooler System Work?

El mud cooler system operates by transferring excess heat from the drilling fluid to a cooling medium, which then dissipates the heat into the environment. The basic process can be broken down into the following steps:

- Circulation of Drilling Fluid: The drilling fluid circulates through the borehole, picking up heat due to friction and the high-pressure environment.

- Fluid Intake: The hot drilling fluid is pumped into the heat exchanger, where it begins to lose heat to the cooling medium (air or water).

- Heat Transfer: The heat is transferred from the drilling fluid to the cooling medium. In water-cooled systems, this is done through direct contact between the fluid and water. In air-cooled systems, air is blown over the fluid via the heat exchanger.

- Cool Fluid Return: Once the temperature of the drilling fluid is reduced, it is pumped back into the drilling circuit, ready to continue its task of cooling the drill bit and transporting cuttings.

- Discharge of Heat: In water-cooled systems, the heated water is often directed to a cooling tower or another heat dissipation system. In air-cooled systems, the heated air is expelled into the atmosphere.

3. Advantages of Using a Mud Cooler System

- Eficiencia de perforación mejorada: By maintaining the proper temperature of the drilling fluid, the mud cooler system ensures the fluid retains its optimal viscosity, improving the efficiency of the drilling operation.

- Prevents Equipment Damage: Overheated drilling fluid can damage the drill bit, pumps, and other critical equipment. The mud cooler system helps prevent this by ensuring the fluid stays within safe temperature limits.

- Reduces Wear on Drilling Equipment: With cooler fluid, there is less friction, reducing wear on the drill string and other equipment, which leads to lower maintenance costs.

- Longer Fluid Life: Drilling fluid that is kept within its ideal temperature range remains stable for longer periods, reducing the need for frequent fluid replacement.

- Energy Efficiency: Modern mud cooler systems are designed to operate efficiently, requiring less energy to cool the fluid compared to older, less optimized systems.

4. Installation and Maintenance of Mud Cooler Systems

4.1. Installation

Installing a mud cooler system involves the following key steps:

- Site Preparation: Choose a location that allows for adequate ventilation and easy access to the drilling operation.

- Component Assembly: Assemble the main components of the system, including the heat exchanger, pumps, filters, y cooling fans (if applicable).

- Fluid Connections: Properly connect the pumps to the drilling fluid circulation system and ensure that the heat exchanger is correctly plumbed into the cooling circuit.

- Electrical and Control Systems: Set up the necessary electrical connections to power the fans, pumps, y temperature sensors. Configure the control system to regulate the system’s operation.

- Testing: Once everything is installed, conduct a thorough test of the mud cooler system to ensure all components are working correctly.

4.2. Maintenance

Routine maintenance is essential to keep the mud cooler system running efficiently. Regular tasks include:

- Cleaning: Periodically clean the heat exchanger and other components to prevent the build-up of debris or contaminants that could affect the system’s performance.

- Checking Fluid Levels: Ensure that the system is properly filled with the correct type and amount of fluid (water or coolant) for efficient operation.

- Inspecting Filters: Regularly inspect and replace the filters to ensure that debris does not enter the system.

- Monitoring Temperature Sensors: Verify that the temperature sensors are working correctly and calibrated for accurate readings.

5. Repair of the Mud Cooler System

If the mud cooler system experiences issues such as reduced cooling capacity or fluid flow problems, the following repair actions may be necessary:

- Replace Worn-Out Parts: Over time, components such as pumps, fans, y temperature sensors may wear out and need replacing.

- Clear Blockages: If the system becomes clogged with debris, disassemble the affected parts and clear any blockages to restore normal operation.

- Seal Leaks: Inspect all connections for leaks, especially around the heat exchanger y pumps, and replace any damaged seals.