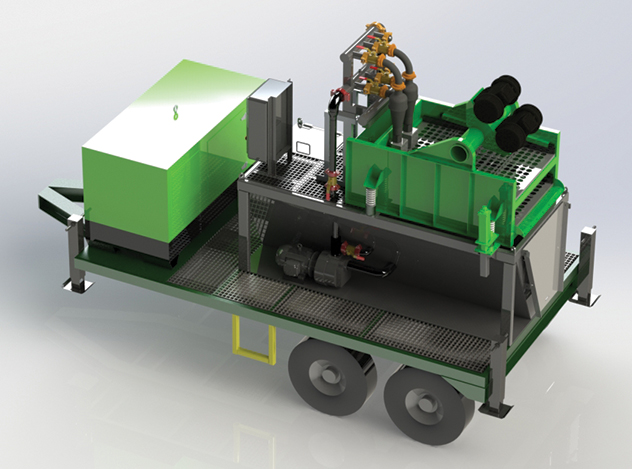

Le Système de recyclage de boue Kemtron est une solution complète qui garantit le recyclage et la réutilisation des fluides de forage, ce qui prolonge leur utilisation et réduit le besoin de boue fraîche. Ceci est particulièrement important dans les environnements où de grandes quantités de fluides de forage sont consommées et où le coût de leur élimination peut être élevé. Le système fonctionne en séparant les particules solides de la boue, permettant au fluide propre d'être réutilisé pour d'autres opérations de forage. Ce système aide à maintenir les propriétés requises de la boue de forage, garantissant une élimination, une lubrification et un refroidissement efficaces.

Le Système Kemtron est conçu avec plusieurs composants essentiels qui fonctionnent ensemble de manière transparente, notamment :

- Agitateurs de schiste: Première ligne de défense dans le processus de filtration. Ils sont utilisés pour éliminer les grosses déblais de forage.

- Nettoyeurs de boue: Ceux-ci sont utilisés après les shakers de schiste pour nettoyer davantage la boue en éliminant les particules plus fines.

- Desanders: Ce sont des équipements qui aident à éliminer les plus grosses particules solides.

- Dessileurs: Ceux-ci raffinent davantage le fluide de forage en filtrant les solides plus petits.

- Centrifugeuses: Pour séparer les particules fines de la boue, augmentant ainsi la qualité du fluide recyclé.

- Pompes de transfert: Pour déplacer la boue nettoyée d'un composant à un autre.

Comment fonctionne le système de recyclage de boue Kemtron

Le Système de recyclage de boue Kemtron fonctionne selon un processus de filtration en plusieurs étapes qui améliore la qualité du fluide de forage, réduit le besoin d'élimination fréquente de la boue et garantit des performances de forage optimales. Voici comment cela fonctionne :

- Séparation initiale: Le fluide de forage, contaminé par des déblais de roche et d'autres particules solides, pénètre dans le agitateur de schiste. Le shaker utilise les vibrations pour filtrer les grosses particules.

- Filtration supplémentaire: Après la séparation initiale, la boue se déplace vers le dessableurs et dessileursCes composants éliminent les petites particules solides du fluide.

- Traitement par centrifugeuse: Le liquide de nettoyage est ensuite traité dans un centrifuger, qui fait tourner la boue à grande vitesse pour séparer les particules encore plus fines. Cela permet d’obtenir un fluide réutilisable de haute qualité.

- Fluide recyclé: Après le processus de centrifugation, la boue propre est renvoyée au appareil de forage où il est réintroduit dans l’opération de forage.

Les avantages de ce système résident non seulement dans le recyclage immédiat du fluide mais également dans le maintien de la viscosité, densité, et propriétés lubrifiantes de la boue. Ceci est crucial pour maintenir l’intégrité du puits de forage et éviter des problèmes tels qu’un tuyau coincé ou un couple excessif pendant le forage.

Principaux avantages du système de recyclage de boue Kemtron

- Rentabilité: Le recyclage des fluides de forage réduit le besoin d’acheter de la nouvelle boue, réduisant ainsi les coûts opérationnels.

- Durabilité environnementale: En réduisant les déchets et en garantissant que moins de produits chimiques nocifs sont éliminés, le système favorise une opération de forage respectueuse de l'environnement.

- Performances améliorées: Le fluide propre et recyclé maintient des conditions de forage optimales, conduisant à un forage plus efficace et à une réduction des temps d'arrêt.

- Durée de vie prolongée de l'équipement: En filtrant les solides nocifs, le Système de recyclage de boue Kemtron réduit l’usure des autres équipements tels que les pompes et les moteurs.

- Conformité réglementaire: De nombreuses opérations de forage sont soumises à des réglementations environnementales strictes, et le système contribue à garantir leur conformité en minimisant les déchets et en garantissant une élimination appropriée de la boue contaminée.

Spécifications techniques

Le Système de recyclage de boue Kemtron est personnalisable en fonction des besoins spécifiques de l’opération de forage. Voici quelques spécifications typiques :

| Composant | Spécification |

|---|---|

| Capacité du shaker de schiste | Jusqu'à 1 500 GPM (gallons par minute) |

| Capacité dessableur | Jusqu'à 1 000 gal/min |

| Capacité du désilteur | Jusqu'à 800 gal/min |

| Capacité de la centrifugeuse | Jusqu'à 200 GPM (pour l'élimination des solides fins) |

| Taille du réservoir de boue | Personnalisable en fonction des besoins du site (généralement 500 – 3 000 BBL) |

| Exigences d'alimentation | 380 V/50 Hz ou 460 V/60 Hz (selon l'emplacement) |

Domaines d'application du système de recyclage de boue Kemtron

Le Système de recyclage de boue Kemtron peut être appliqué dans divers secteurs, notamment :

- Forage pétrolier et gazier: Que ce soit à terre ou en mer, le système est inestimable pour maintenir l’efficacité du forage et réduire l’impact environnemental.

- Exploitation minière: Dans les opérations minières, le système est utilisé pour nettoyer les fluides qui facilitent le forage dans la roche et le sol, en maintenant un approvisionnement constant en fluide propre pour les opérations.

- Forage géotechnique: Pour les investigations de forages profonds, où un fluide continu et propre est essentiel pour éviter la contamination des échantillons.

Conclusion

En conclusion, le Système de recyclage de boue Kemtron joue un rôle essentiel pour garantir l’efficacité, la durabilité et la rentabilité des opérations de forage grâce à ses composants de filtration avancés, notamment. secoueurs de schiste, nettoyeurs de boue, et centrifugeuses, le système permet la réutilisation des fluides de forage, réduisant ainsi le besoin de nouveaux matériaux tout en minimisant l'élimination des déchets. En améliorant les performances de la boue de forage, il permet une élimination, une lubrification et un refroidissement plus efficaces, contribuant ainsi à des opérations de forage plus sûres et plus rapides. De plus, le système aide les entreprises à répondre aux exigences réglementaires et à améliorer leurs efforts en matière de durabilité environnementale, ce qui en fait un élément crucial de la technologie de forage moderne.