PRODUITS

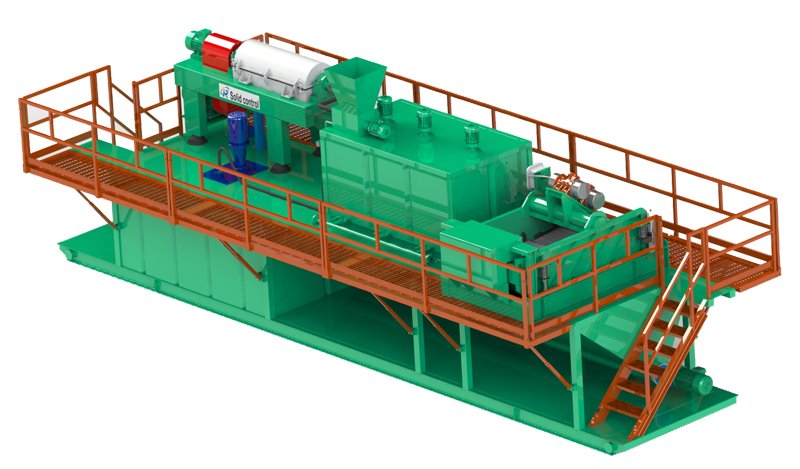

Sludge Dewatering Unit

Structure du produit

The Sludge dewatering unit is a key component of the close loop.It will act as an aid of the solids control equipment.It is not possible to remove colloidal particles making the waste mud reusable in the drilling operation.If required,this Sludge Dewatering Unit can be used for waste treament with final disposal purposes.Numerous studies and experiments as well as documentation of field applications have taken place in the oil and gas industry in recent years. Sepatation limitations of mechanical equipment typically used in drilling operations is approxmately 3 microns.It can be achieved by a essentially all of the suspended solids from the feed slurry.

The Sludge Dewatering Unit process used is a combination of several mechanical components each with a specific function.

Sludge dewatering Unit is composed of dewatering device, centrifuges and screw pump.

the waste mud is taken from the active system.then the mud is pumped through the Sludge dewatering unit.Coagulants and flocculants are added to the sludge dewatering system to improve solid separation.Final stage is the processing of the flocculants mud through the high speed centrifuge.The liquid recovered, free of solids is returned back to the system.the solids removed are collected in the cuttings catch tank for final disposal in the polygon.

Three steps of sludge dewatering Unit

1.Delivery

Pumping the liquid to the dewatering system and pumping/metering polymer into the flocculation manifold.

2.Blending

Mixing liquid waste from the barge or active system mud,dilution(if necessary),and polymers,in the desired proportions to flocculate the slurry prior to the centrifuge.

3.Separation

Separate the flocculated slurry intro a solids sludge and clear, re-usable liquid, with a high speed centrifuge. The methods used to accommodate these three segments may vary from one Sludge Dewatering Unit to another. But the basic delivery,blending,and separation functions are the key elements in any dewatering process.

The Sludge Dewatering Unit is designed to treat waste mud from either a waste pit or holding tank to prduce clean water.It is suitable for re-use on site and a solid whcih more easily handled and disposed of.

The Sludge Dewatering Unit system comprises a containerised chemical treatment system and a high centrifuge complete with a feed pump,electrical control system and all ancillary piping,hoses and gauges.This unit also incorporates a small workbench area.

We are an exporter of Drilling Mud Centrifuges. Our factory approval the API. TR solids control is the designed, selling, production, service and delivery of drilling shale shaker et shaker screens manufacturers. We will provide the high quality Decanter Centrifuge and best service. Your best mud centrifuges start from TR solids control.