In the oil and gas industry, efficiency and performance are paramount to a successful drilling operation. One of the key components that contribute to improved performance is the dispositif trembleur de schiste de forage. These machines, though often overlooked, play a vital role in optimizing drilling performance by effectively managing the drilling fluid. Their primary function is to remove solid debris from the drilling fluid, which helps maintain the quality of the fluid and prevents issues that could slow down or disrupt drilling operations. In this article, we will explore the crucial role of drilling shale shakers in maximizing drilling performance, including how they function, their benefits, and why they are indispensable in modern drilling operations.

What is a Drilling Shale Shaker?

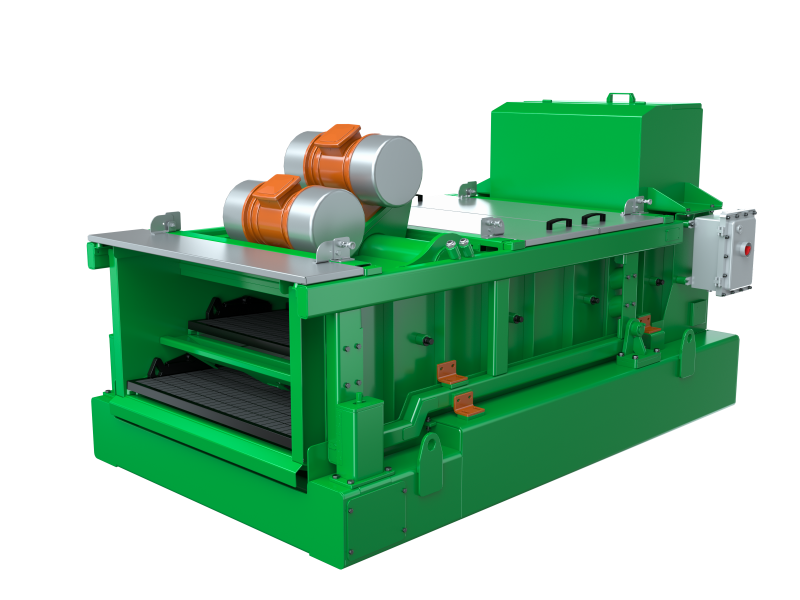

UN dispositif trembleur de schiste de forage is a type of vibrating screen designed to separate solid particles (commonly referred to as cuttings) from the drilling fluid (also known as mud) during the drilling process. As the drill bit cuts through the formation, it generates solid debris, which can compromise the quality of the fluid. The shale shaker screens these solids out, allowing the clean fluid to be recirculated into the drilling system.

By maintaining the integrity of the drilling fluid, shale shakers help ensure that the drilling process runs smoothly and efficiently. In addition to this, they contribute to enhancing drilling performance in several ways, such as reducing downtime, improving penetration rates, and reducing wear on equipment.

Table 1: Key Functions of Drilling Shale Shakers

| Fonction | Description |

|---|---|

| Solids Removal | Shale shakers remove solid particles from drilling fluid, maintaining fluid quality. |

| Fluid Recovery | Clean fluid is recovered and recirculated for continued use in the drilling process. |

| Efficiency Boost | By keeping the fluid free of debris, shale shakers optimize the drilling performance. |

| Avantages environnementaux | Proper waste management ensures minimal environmental impact during operations. |

The Importance of Drilling Fluid in Performance

Drilling fluid is a critical component in any drilling operation. It serves various functions, including:

- Lubricating the drill bit to reduce friction and wear.

- Carrying cuttings from the drill site to the surface, which prevents clogging and keeps the borehole clear.

- Cooling the drill bit to prevent overheating.

- Maintaining hydrostatic pressure to control well pressure.

The performance of the drilling fluid is directly linked to the quality of the shale shaker operation. If solids accumulate in the fluid, it can alter its properties, causing increased viscosity, reduced cooling efficiency, and even equipment failure. By filtering out these solids, shale shakers ensure that the drilling fluid remains effective and efficient throughout the drilling process.

Table 2: Functions of Drilling Fluid

| Fonction | Importance for Drilling |

|---|---|

| Lubrification et refroidissement | Reduces wear and tear on drill bits, allowing for smoother drilling operations. |

| Cuttings Transport | Prevents the build-up of debris, ensuring that the borehole remains clear. |

| Pressure Management | Helps maintain well control, preventing blowouts and other dangerous situations. |

| Maintaining Fluid Viscosity | Ensures the fluid maintains the right properties for optimal performance. |

How Drilling Shale Shakers Maximize Drilling Performance

1. Maintaining Fluid Consistency

Drilling fluid needs to maintain a specific viscosity and density to function effectively. Solid particles that accumulate in the fluid can increase its viscosity, which leads to problems such as sluggish fluid movement, blocked circulation, and overheating. This can reduce the efficiency of the drilling process and result in unnecessary downtime.

Shale shakers remove the solid cuttings from the drilling fluid, helping to maintain its desired viscosity. As a result, the fluid can flow more freely, allowing the drill bit to operate at peak performance and reducing the risk of encountering issues that slow down drilling operations.

Table 3: Impact of Shale Shakers on Fluid Consistency

| Fluid Property | Effect on Drilling Performance |

|---|---|

| Viscosity | Clean fluid with optimal viscosity allows for smoother drilling and prevents fluid blockage. |

| Débit | Maintaining a consistent fluid flow supports faster drilling and more efficient cuttings removal. |

| Cooling Effect | Proper fluid properties ensure that the drill bit stays cool and operates efficiently. |

2. Reducing Equipment Wear and Tear

Excessive solids in the drilling fluid can cause significant wear on drilling equipment, particularly the drill bit. Solid debris can cause abrasion, increasing the frequency of equipment repairs and replacements. This leads to increased operational costs and downtime.

By removing the cuttings before they reach the drill bit, shale shakers reduce the amount of debris that comes into contact with equipment. This minimizes wear and tear, helping to extend the life of critical components and reduce the need for maintenance. The result is a more efficient and cost-effective drilling operation.

Table 4: Benefits of Reducing Equipment Wear

| Avantage | Impact on Drilling Efficiency |

|---|---|

| Longer Equipment Life | Reduced frequency of repairs and replacement parts. |

| Fewer Breakdowns | Minimized downtime for maintenance and repairs. |

| Économies de coûts | Lower costs for equipment maintenance and replacement. |

3. Increasing Drilling Speed

The faster a drilling operation progresses, the lower the overall costs will be. Drilling speed can be limited by several factors, such as bit performance, fluid quality, and cuttings removal. Shale shakers play a crucial role in optimizing drilling speed by removing solids from the drilling fluid, which improves the efficiency of the drilling process.

Clean drilling fluid reduces the friction between the drill bit and the formation, which leads to better penetration rates. Additionally, the proper circulation of fluid helps to maintain consistent cooling and lubrication, further improving drilling speed.

4. Minimizing Rig Downtime

Rig downtime is a significant concern for drilling operations, as it represents lost revenue. When the drilling fluid becomes contaminated with cuttings or other solids, it may be necessary to shut down operations to clean or replace the fluid. This leads to downtime and reduced productivity.

Drilling shale shakers help to minimize downtime by continuously filtering the fluid and removing solid particles. By ensuring that the fluid remains clean and effective, shale shakers reduce the need for frequent fluid changes or treatments, allowing operations to continue without interruption.

Table 5: Impact of Shale Shakers on Downtime

| Factor | Impact on Rig Downtime |

|---|---|

| Continuous Solids Removal | Keeps the drilling fluid clean, reducing the need for interruptions. |

| Fewer Fluid Changes | Eliminates the need for frequent replacements or treatments of drilling fluid. |

| Reduced Equipment Maintenance | Minimizes the risk of equipment failure, reducing time spent on repairs. |

5. Avantages environnementaux

Environmental sustainability is an increasingly important aspect of modern drilling operations. Drilling shale shakers contribute to a more environmentally friendly process by efficiently managing waste and minimizing contamination.

By removing solid particles from the drilling fluid, shale shakers reduce the volume of waste that needs to be disposed of. The solid cuttings can be treated and disposed of in a more environmentally responsible manner, while the cleaned fluid can be reused, reducing the need for fresh water and other resources.

Conclusion

Drilling shale shakers play a vital role in maximizing drilling performance. By maintaining the quality of the drilling fluid, they help to reduce equipment wear, improve drilling speed, minimize downtime, and reduce environmental impact. As a result, shale shakers are indispensable tools in the oil and gas industry, contributing to more efficient and cost-effective operations.