Solids control equipment plays a crucial role in the drilling industry, particularly in oil and gas exploration and drilling operations. Its primary function is to manage and remove solid particles, such as cuttings and debris, from the drilling fluid. This is essential for maintaining the quality of the drilling fluid, ensuring the efficiency of the drilling process, and extending the lifespan of the equipment involved. By effectively managing solids, these systems help reduce operational costs and improve overall performance.

1. Understanding Solids Control Equipment

Solids control equipment refers to a set of specialized machinery designed to separate solid particles from the drilling fluid (also known as "mud"). During drilling, the fluid circulates to cool the drill bit, carry cuttings to the surface, and stabilize the borehole. As drilling progresses, solid particles, including rock cuttings, metal filings, and other debris, accumulate in the fluid. Without proper management, these solids can damage equipment, reduce drilling efficiency, and compromise safety.

Solids control systems are designed to remove these particles, preventing them from interfering with the flow and quality of the drilling fluid. The key equipment components include shale shakers, desanders, desilters, centrifuges, and mud cleaners.

2. Types of Solids Control Equipment

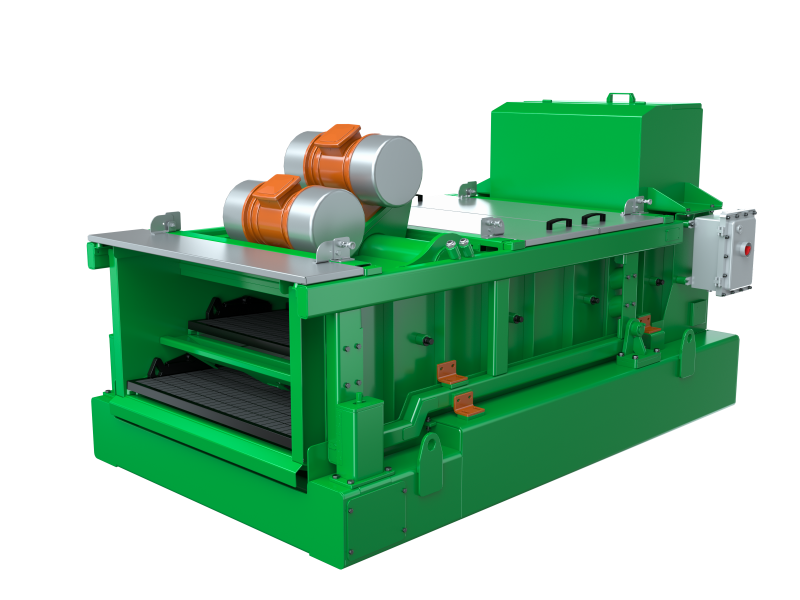

- Shale Shaker: The shale shaker is the first line of defense in the solids control system. It uses vibrating screens to separate large solids from the drilling fluid. The shaker's primary function is to remove oversized particles, ensuring the fluid remains clean and efficient for reuse.

- Desander: A desander is used to remove sand-sized particles (typically ranging from 40 to 100 microns) from the drilling fluid. This equipment uses hydrocyclones, which create a centrifugal force to separate the solid particles from the fluid. It plays a vital role in protecting downstream equipment like pumps and mud motors from wear.

- Desilter: Similar to a desander, a desilter removes smaller particles (usually in the range of 20 to 40 microns). Desilters are used to further purify the drilling fluid and ensure that it meets the required specifications for proper circulation and wellbore stability.

- Centrifuge: A centrifuge is used to separate finer solids from the drilling fluid. It operates on the principle of centrifugal force, using a rotating drum to create high-speed forces that separate solids based on their size and density. Centrifuges are typically used for the final stage of solids control to remove very fine particles.

- Mud Cleaner: A mud cleaner combines the functions of both the shale shaker and the desander/desilter. It has a series of vibrating screens and hydrocyclones, which allow it to remove solids of various sizes. Mud cleaners are often used in situations where space is limited, or a more compact system is needed.

3. Importance of Solids Control Equipment

The importance of solids control equipment cannot be overstated in modern drilling operations. Some of the key benefits include:

- Improved Drilling Efficiency: By removing solid particles from the drilling fluid, solids control equipment ensures that the fluid maintains its lubricating and cooling properties. This helps the drill bit operate more efficiently, reducing the likelihood of damage and extending its lifespan.

- Cost Reduction: Effective solids management allows for the reuse of drilling fluid, reducing the need for frequent replacement and disposal of waste material. This results in significant cost savings for drilling operations.

- Enhanced Equipment Lifespan: Solid particles can cause erosion and wear on critical components like pumps and motors. By removing these particles, solids control equipment helps protect expensive machinery from damage, thereby extending its operational life.

- Environmental Protection: Solids control systems also play a role in minimizing the environmental impact of drilling operations. By ensuring that the drilling fluid is properly cleaned and recirculated, these systems reduce the amount of waste material that needs to be disposed of, thereby decreasing environmental pollution.