-

4 Common Types of Shale Shaker Screens and Their Features

2025-08-22Shale shaker screens are usually woven from metal wire or fiber wire, with an opening size between 0.15–1 mm. They are mainly used to remove and recover different types of fine suspended solids from drilling mud. Screen separation is simple, efficient, and cost-effective, which makes it a widely used method in oilfield drilling solids control systems. There are many kinds of shaker screens, but today let’s look at four of the mos...

-

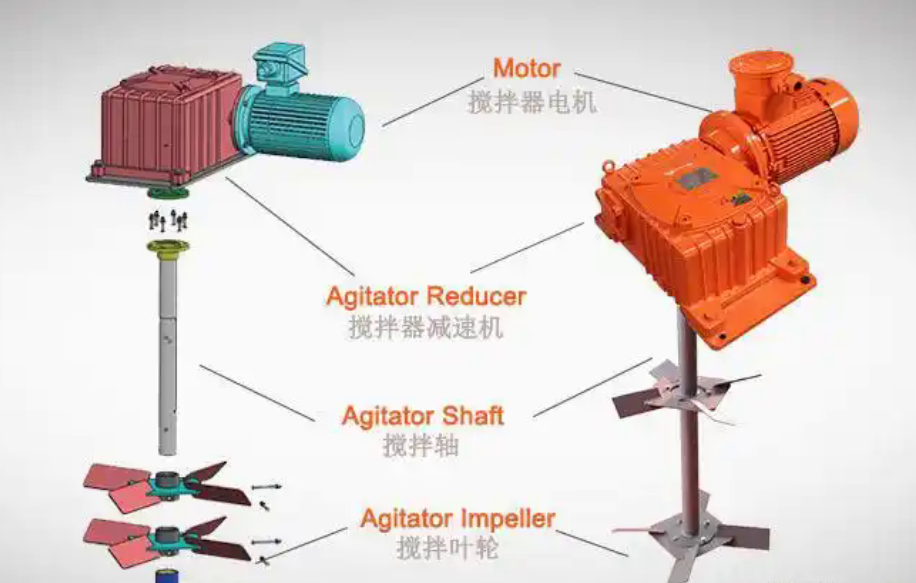

Types of Drilling Mud Agitators and Their Applications

2025-08-22Mud agitators can actually be divided into different types depending on how the gearbox and motor are connected, the shape of the impeller, the type of fluid being mixed, and their specific application. For example, by gearbox connection, they can be worm-gear type or bevel-gear type; by impeller design, they can be flat-blade, pitched-blade, or helical-blade; by flow pattern, they can be axial flow, radial flow, or mixed flow; and ...

-

How to Select a Drilling Fluid Mud Agitator

2025-08-15A drilling fluid mud agitator is a specialized device used in petroleum drilling for solids control. It comes in various specifications and models, and agitators designed for industries like chemicals, oil refining, or food processing cannot be directly applied. Here are four key factors to consider when choosing a mud agitator, optimized for clarity and user readability based on Google search trends and user preferences. Mu...

-

Innovative Multi-Stage Solids Control Shale Shaker – Revolutionizing Drilling Mud Treatment

2025-08-15The innovative multi-stage solids control shale shaker is a groundbreaking advancement over traditional drilling mud shale shakers. Through technical upgrades—such as increasing the vibration motor power, replacing the single-piece screen design with modular screens, introducing a pneumatic screen tightening system instead of traditional wedge blocks, enlarging the shaker box volume and screen area—it delivers enhanced performance a...

-

How to deal with drilling fluid shaker screen slurry leakage

2025-07-31This phenomenon is primarily related to factors such as the high solids content in the drilling fluid, high mud viscosity, and dispersed drill cuttings. It is also related to the inherent characteristics of the shaker screen, such as low vibration force, high mesh count, and small screen area. It is also significantly affected by the direction and location of the shaker screen's inlet during on-site installation. This can be analyze...

-

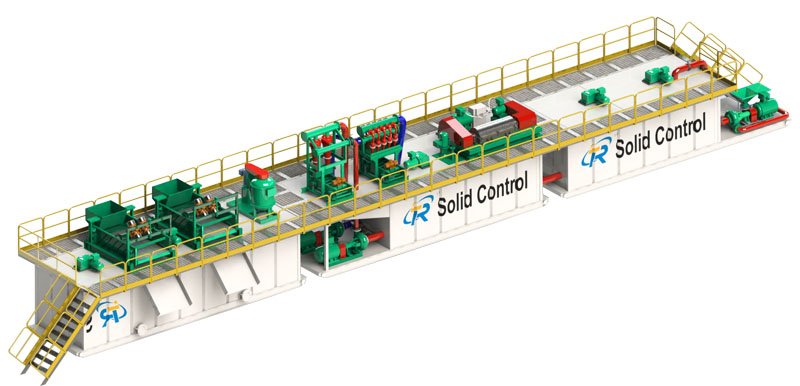

Classification and selection of solids control mud tanks

2025-07-31The mud tank in solid control systems serves as critical equipment for mud storage, blending, solid-liquid separation, and circulation. As an integral component of the mud circulation system, it facilitates mud transfer from the wellhead to mud pumps. Solid control equipment mounted on the tank separates drilling solids from the mud, which is then conditioned and blended through the weighting and mixing system to meet drilling proce...

-

Centrifuges in Drilling Solid Control Systems vs. Mud Conservation Systems

2025-07-25Centrifuges are commonly used in both drilling solid control systems and mud conservation systems, but what’s the difference between the centrifuges in each system? Centrifuge in Drilling Solid Control Systems In drilling solid control systems, the centrifuges are typically medium to low-speed ones. This is because the solid control system uses multiple stages of filtration. After the drilling fluid passes through the shal...

-

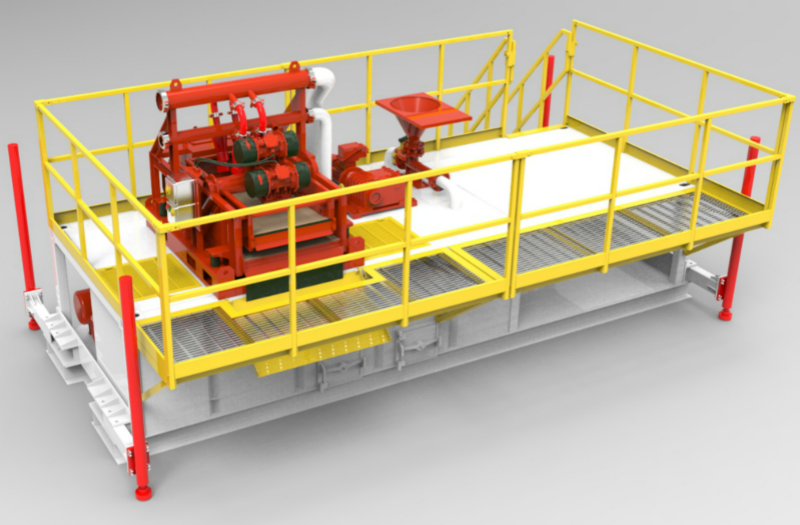

Comparison between skid-mounted solids control system and vehicle-mounted solids control system

2025-07-25The drilling solid control system is designed to effectively manage and separate solid particles in drilling fluids, ensuring that the drilling mud can be recycled. It's also known as the mud purification system. There are two main types of solid control systems: the skid-mounted solid control system and the truck-mounted solid control system. Both have their unique features and advantages. Skid-Mounted Solid Control System: ...

-

Requirements for solids control in coalbed methane drilling

2025-07-18At present, the drilling methods for ground coalbed methane extraction mainly include conventional vertical wells, cluster wells, and multi-branch horizontal wells in terms of well types. In terms of drilling circulating media, there are mainly two methods: water-based drilling fluid and air drilling. Characteristics of coal seamsThe coal seams are usually referred to as methane gas in coal seams, which mainly exist in the coal s...

-

6 Precautions for Using Drilling Fluid Vibrating Screen

2025-07-18The drilling fluid vibrating screen is a primary solid control device for drilling mud. Some customers use double or triple vibrating screens. The drilling fluid vibrating screen has the characteristics of high vibration intensity, large screening area, adjustable screen box angle, and compact structure. How to use the drilling fluid vibrating screen correctly has become a concern for everyone. Here are 6 major precautions fo...

-

How to deal with muddy sewage generated by construction piling

2025-07-11The mud sewage treatment system generated by construction piling directly affects the quality and progress of the project. The technical problem of treating construction piling mud sewage is one of the more prominent problems in the current piling project.The traditional backward treatment method of piling mud sewage is natural drying method. This method is primitive and backward, and there are many subsequent problems, such as: hig...

-

Comparison of 4 oilfield sludge treatment processes

2025-07-11The more common oilfield sludge treatment processes are: 1) incineration 2) biological method 3) solvent extraction 4) thermal desorption. In comparison with the four sludge treatment processes, each has its own advantages and disadvantages, and the specific selection is based on the different requirements and working conditions of the oilfield project. Oilfield sludge refers to the sludge produced during the oil extraction, tran...

-

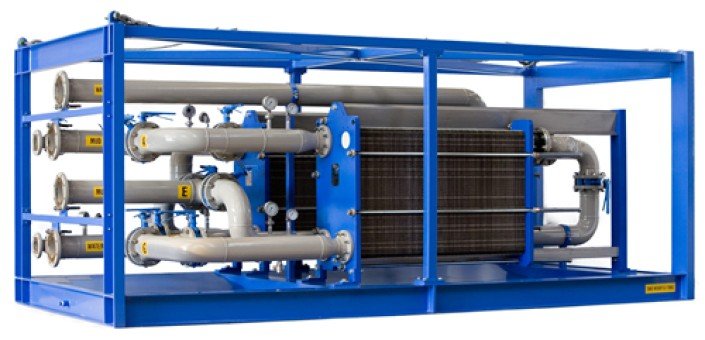

Drilling Mud Cooling Equipment

2025-07-04The drilling mud cooling equipment consists of three parts: exhaust system, water cooling system, mud system, etc. Mud cooling equipment is also called mud cooling device, mud cooling tower, etc. It is generally erected in the mud pool to cool the high-temperature mud. Working principle of drilling mud cooling equipmentThe basic principle of cooling system and fan cooling mud is to use air and mud to directly contact, and tak...

-

Oil sludge hot water washing method: oil sludge treatment equipment and oil sludge treatment system

2025-07-04What is oil sludge? Oil sludge is also called oily sludge, oily sludge sand, and ground oil sludge. During the drilling process, the oily sludge brought out when the drilling rig is replaced and the casing is extracted is left around the well site. These oily sludges are wrapped with various mud and sand and debris. There is no time to deal with them on site, so they are temporarily piled up at the well site. The more they pile ...

-

Drilling mud is processed while drilling and centrally without falling to the ground

2025-07-04When choosing a solution for oilfield drilling, it is necessary to choose mud-free drilling treatment or mud-free centralized treatment according to the actual working conditions of the well site. This article will briefly introduce the two methods of mud-free drilling treatment and mud-free centralized treatment. Mud-free drilling treatmentDrilling mud-free drilling treatment means that the mud-free system supporting the dri...

-

Types of Derricks

2025-07-03Basic Knowledge of Drilling Derrick and Substructure Definition of Derrick A drilling derrick is a tower-like steel structure used to mount hoisting equipment such as the crown block, traveling block, and hook. It bears the loads generated during drilling, casing operations, and other related work. It provides the necessary height and space for lifting and lowering operations and for storing tubulars. The derrick ty...

-

7 major solids control equipment in oil drilling solids control system

2025-06-27The oil drilling solids control system is composed of solids control equipment. It is one of the eight major equipment in drilling engineering and plays an important role. Today, we will share the eight major solids control equipment in the drilling solids control system, namely: drilling fluid vibrating screen, vacuum degasser, drilling fluid desander, drilling fluid desilter, drilling fluid centrifuge, liquid-gas separator, mud ag...

-

6 key points of drilling mud circulation system

2025-06-27The drilling mud circulation system needs to understand the following 6 points: the role of the mud circulation system, equipment composition; the layout, classification and system of the mud circulation system, etc. The role of the mud circulation systemThe drilling mud circulation system plays the role of purifying and recycling the circulating mud in the drilling rig. The mud circulation system can prepare mud suitable for...

-

Sources, Composition, and Classification of Drilling Waste Mud in Oil and Gas Mining

2025-06-13Source of waste drilling mud The main source of waste drilling mud is the production during the process of oil and gas excavation, mining, and well repair. Drilling fluid is the blood of oil and gas drilling and an important component to ensure the smooth progress of the entire mining work. Drilling mud can carry the cuttings produced during the drilling process, cool and lubricate the drill bit and drilling tools, protect t...

-

Environmental Impact and Treatment Technologies of Drilling Waste: Challenges and Solutions

2025-06-13The pollution caused by drilling waste to the environment is mainly due to the presence of a large amount of water-soluble heavy metal ions and inorganic substances in drilling waste. After these substances are dissolved in surface and groundwater, they will gradually spread and transfer over time, and eventually bring great threats and impacts to the living environment of animals and plants, and even cause the death of animals and ...

-

Derick Shaker Spare Parts: Components and Functions

2025-05-23Derick shakers are essential in solids control systems, helping to separate large particles from drilling fluids. Key spare parts for Derick shakers include: Shaker Screens: These are the primary components for particle separation. They come in various mesh sizes to filter out specific solid particles from the drilling mud. Regular replacement ensures efficient fluid circulation and equipment protection. Vibrating Motors: The...

-

Solids Control Equipment: Essential for Drilling Operations

2025-05-23Solids control equipment plays a crucial role in the drilling industry, particularly in oil and gas exploration and drilling operations. Its primary function is to manage and remove solid particles, such as cuttings and debris, from the drilling fluid. This is essential for maintaining the quality of the drilling fluid, ensuring the efficiency of the drilling process, and extending the lifespan of the equipment involved. By effectiv...

-

Mud Recycling System: Understanding Key Components and Their Functions

2025-04-25In industries like drilling, construction, and waste management, mud recycling systems are vital for ensuring efficient and environmentally friendly operations. These systems are designed to treat and reuse drilling fluids, also known as "mud," which is used during the drilling process to maintain pressure and carry debris to the surface. Below, we will explore the key components of a mud recycling system, their functions, and how th...

-

How Drilling Shale Shakers Improve Efficiency in Oil and Gas Extraction

2025-02-21A drilling shale shaker is a mechanical device used in the oil and gas industry to separate solids (such as shale, cuttings, and other debris) from the drilling fluid (also known as mud). It works by using vibrating screens to filter the solids from the liquid. The clean liquid is then recirculated into the drilling process, while the solids are removed for disposal. The separation of solids is essential for maintaining the quality ...

-

Key Considerations When Choosing a Drilling Shale Shaker for Your Operations

2025-02-21In the oil and gas drilling industry, effective drilling fluid management is crucial for the success of operations. One of the most important tools used for drilling fluid separation is the drilling shale shaker. A shale shaker's main function is to separate solid particles (shale) from drilling fluids (also known as mud), which is vital for ensuring smooth drilling operations and maintaining optimal fluid performance. Choosing t...

-

Mud Cooler System: Overview, Components, Functionality, and Maintenance

2025-01-03A mud cooler system is designed to maintain the ideal temperature of the drilling fluid by removing excess heat generated during the drilling process. Drilling fluid plays a vital role in cooling the drill bit, lubricating the drilling string, and transporting cuttings from the borehole to the surface. However, as the fluid circulates, it can heat up, especially when the drilling operation involves high-speed rotations and increased...

-

HDD Mud Mixing System: Overview, Installation, Maintenance, and Repair

2025-01-03The HDD (Horizontal Directional Drilling) mud mixing system is a critical component in the HDD drilling process. It is designed to prepare and mix the drilling fluid, also known as "mud," which is essential for cooling the drill bit, lubricating the drill string, and transporting the cuttings to the surface. A well-functioning mud mixing system ensures smooth and efficient drilling operations, minimizing downtime and improving the o...

-

Exploring the Aphron Mud System: A Comprehensive Guide for Oil and Gas Drilling

2024-11-29In the world of oil and gas drilling, technological advancements continually push the boundaries of what's possible, improving efficiency and safety while minimizing environmental impact. One such innovative technology is the Aphron Mud System, a cutting-edge approach to drilling fluid formulations that has revolutionized drilling operations. In this article, we will delve deep into the Aphron Mud System, exploring its components, b...

-

Portable Mud Systems for Water Wells: The Ultimate Solution for Your Drilling Needs

2024-11-29When it comes to water well drilling, one of the most important factors for efficiency and success is the use of high-quality portable mud systems. Whether you're drilling in remote locations or need a solution that offers portability and convenience, portable mud systems Midland TX is a growing demand. In this guide, we’ll explore the importance of these systems, how they work, and why they are becoming the go-to choice for many wa...