In the world of horizontal directional drilling (HDD) and other underground construction techniques, drilling mud circulation systems are critical to the efficiency, safety, and success of projects. These systems are designed to pump and circulate drilling fluids (commonly referred to as drilling mud) to support the drilling process, remove cuttings, stabilize the borehole, and lubricate the drill bit. A well-maintained and properly designed mud circulation system can significantly improve the overall performance of your drilling operations.

In this article, we will delve into the importance of drilling mud circulation systems, the key components, benefits, and best practices for maintaining and optimizing your system. Along the way, we’ll explore a variety of related keywords such as mud recycling, mud pumps, mixing systems, and cuttings management, all of which contribute to the success of trenchless projects.

Understanding the Role of Drilling Mud Circulation

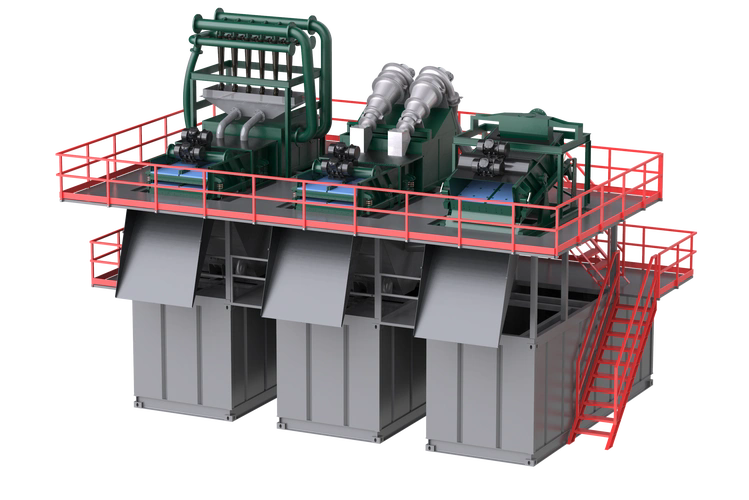

Drilling mud circulation serves a multi-faceted role in horizontal directional drilling. The mud circulation system is responsible for continuously pumping and circulating drilling fluid down the drill string and back up the borehole, carrying rock cuttings with it. The system typically includes a combination of mud pumps, mixing tanks, and recycling units, all of which ensure the mud maintains the proper viscosity and consistency for effective drilling.

Key Components of a Drilling Mud Circulation System

A well-functioning mud circulation system is made up of several essential components that work together to ensure that the drilling fluid performs optimally throughout the process. These components include:

- Mud Pumps: These pumps provide the necessary pressure to circulate the drilling fluid through the drill pipe and up the borehole. Mud pumps are essential for maintaining fluid flow during drilling operations.

- Mixing Tanks: Mixing tanks are used to blend water, clay, and other additives to create the proper drilling fluid. The mixture is then stored in the tank before being pumped into the system.

- Mud Cleaners: These are used to filter out large debris and rock cuttings from the drilling fluid, ensuring that the mud remains effective for circulation.

- Shale Shakers: Often used in conjunction with mud cleaners, shale shakers separate fine particles from the fluid, ensuring that the mud does not become too thick or too diluted.

- Mud Recycling Units: A mud recycling system allows contractors to reclaim and reuse the drilling fluid, saving money and reducing environmental impact by minimizing waste.

Importance of Maintaining Proper Mud Circulation

The primary purpose of a mud circulation system is to facilitate the removal of drill cuttings and maintain the stability of the borehole. Let’s break down the key benefits of an effective mud circulation system:

1. Efficient Cuttings Removal

The circulation system ensures that rock and soil cuttings produced by the drill bit are carried away from the borehole. Without a well-maintained circulation system, these cuttings would accumulate, potentially causing the borehole to become clogged and jeopardizing the progress of the project.

2. Hole Stabilization

The circulating drilling fluid also helps stabilize the borehole. By maintaining pressure within the hole, the mud prevents the collapse of the surrounding soil or rock, which could lead to dangerous situations or delays.

3. Lubrication and Cooling

Drilling mud also serves as a lubricant for the drill bit, reducing friction and preventing overheating. The ability of the system to maintain a consistent fluid flow ensures that the drilling bit operates at peak performance for longer periods, reducing wear and tear.

4. Preventing Wellbore Instability

Drilling fluid helps prevent the wellbore from collapsing, especially when drilling through unstable or loose formations. An adequate mud circulation system helps to minimize wellbore instability, which can lead to costly delays or even complete project failure.

Mud Recycling Systems: Environmental and Cost Benefits

One of the key innovations in modern drilling mud circulation systems is the ability to recycle drilling fluid. By investing in a mud recycling unit, drilling contractors can save money on fluid disposal and reduce environmental waste. Mud recycling helps to reduce the amount of fresh material needed for the drilling operation, making it a more sustainable choice.

Benefits of Mud Recycling:

- Cost Savings: Recycling drilling mud reduces the need to purchase new fluid, which can be costly, especially on large projects.

- Environmental Impact: By recycling and reusing the mud, contractors minimize the waste generated by the drilling process, reducing the environmental footprint.

- Continuous Operation: Mud recycling ensures that the drilling operation can proceed uninterrupted, as contractors can keep reusing the fluid without delays for disposal and refilling.

Below is a table showing the environmental and financial benefits of mud recycling in HDD operations:

| Benefit | Explanation |

|---|---|

| Cost Reduction | Reduces costs by minimizing the need for fresh drilling fluids. |

| Waste Reduction | Minimizes waste disposal by recycling mud for continuous use. |

| Improved Efficiency | Keeps the drilling process running smoothly without interruptions for mud replenishment. |

| Regulatory Compliance | Helps meet environmental regulations by limiting fluid disposal. |

Choosing the Right Drilling Mud Circulation System

Selecting the right mud circulation system depends on a variety of factors, including the scale of your project, the type of terrain, and the specific needs of your drilling operation. Here are some considerations when choosing a circulation system:

1. Flow Rate and Pump Capacity

The flow rate of the system should match the requirements of the drill size and the expected rate of penetration. Larger projects, such as pipeline installations, may require high-capacity pumps and larger mixing tanks.

2. Mud Consistency Control

It’s essential to maintain the right consistency and viscosity of the drilling fluid. A system that offers real-time monitoring and adjustment of mud properties will help optimize drilling efficiency and reduce the chances of downhole problems.

3. Recycling Capabilities

If you're working on a large-scale project or aiming to reduce environmental impact, you should prioritize mud recycling units that help you reclaim fluid for reuse. This will not only save on material costs but also help you comply with environmental regulations.

4. Ease of Maintenance

Mud circulation systems that are easy to maintain and service will keep your project on track. Look for systems with accessible parts and clear maintenance procedures to minimize downtime.

Best Practices for Maintaining Drilling Mud Circulation Systems

To maximize the lifespan and effectiveness of your mud circulation system, it's important to follow best practices for maintenance. Proper care will ensure your system runs smoothly, reduces downtime, and extends the equipment's service life. Here are some tips:

1. Regular Inspection of Mud Pumps

Ensure that the mud pumps are regularly inspected for wear and tear. Replace parts like seals and valves as needed to prevent leaks and maintain proper fluid flow.

2. Keep Mixing Tanks Clean

Cleaning the mixing tanks regularly helps prevent the buildup of residual mud and ensures the system continues to mix the fluid properly.

3. Monitor Mud Quality

Constantly monitor the quality of the mud for its viscosity and density. This ensures the mud is functioning as intended for lubrication, cooling, and cuttings removal.

4. Use High-Quality Mud Additives

Choosing high-quality additives that enhance the performance of the drilling mud is essential. These can improve hole stability, reduce friction, and prevent clogging in the system.

5. Optimize Recycling Processes

Incorporate efficient mud recycling processes to ensure that fluids are not wasted. This helps keep your costs low and reduces your environmental impact.

In conclusion, a drilling mud circulation system plays a pivotal role in ensuring the efficiency, safety, and success of any horizontal directional drilling operation. By maintaining proper circulation, ensuring the mud remains at the right consistency, and investing in mud recycling, contractors can significantly enhance the performance of their drilling projects.

From improved cuttings management to hole stabilization and cost savings through recycling, the advantages of a well-functioning circulation system are clear. By understanding the key components, benefits, and best practices outlined in this guide, you can optimize your drilling mud circulation system and achieve a smoother, more successful drilling experience.

So, whether you're working on a small utility project or a large-scale pipeline installation, consider the role that a quality circulation system plays in your project’s success. Investing in the right system can save time, reduce costs, and help you achieve superior results.