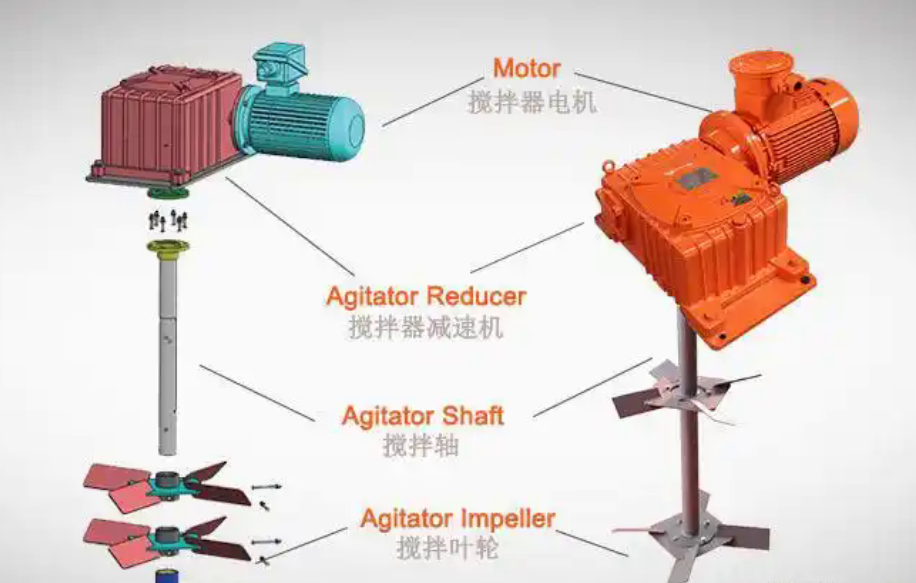

A drilling fluid mud agitator is a specialized device used in petroleum drilling for solids control. It comes in various specifications and models, and agitators designed for industries like chemicals, oil refining, or food processing cannot be directly applied. Here are four key factors to consider when choosing a mud agitator, optimized for clarity and user readability based on Google search trends and user preferences.

- Mud Agitator Speed

In petroleum drilling solids control, to prevent drill cuttings from being crushed during agitation, the agitator speed should not be too high. Ideally, the speed should range between 50–60 rpm. Agitators exceeding 60 rpm should be approached with caution. - Mud Agitator Power

Practical measurements of mud agitator power consumption show that the actual output power typically does not exceed 2 kW. Currently, agitators with 7.5 kW or 5 kW motors are available on the market. These higher-power designs aim to restart the impeller even when buried in settled sand. However, this often leads to motor burnout or impeller breakage. Modern mud agitators incorporate structural improvements, such as devices that lift the impeller to a certain height after stopping, minimizing the impact of settled sand. - Agitator Sealing

Due to harsh operating conditions, the shaft of a drilling fluid mud agitator is not suitable for end-face sealing, and standard packing seals are often inadequate. The most effective solution is the use of multiple V-type packing sets, which offer self-sealing and self-compensating capabilities. These seals require minimal maintenance and adjustments over time and effectively prevent lubricant leakage. - Impeller Selection

Mud agitator impellers come in various designs, including single and double impellers. A key consideration is that small-diameter, high-speed impellers produce low circulation volume and high shear force, making them unsuitable for suspending solids in drilling fluid. Therefore, impellers with larger diameters are generally preferred. Additionally, mud agitators are divided into worm gear and helical gear types. The open turbine impeller, widely used in drilling fluid agitators, is the most effective as it lacks a central disc, allowing unobstructed convective mixing of the liquid phases above and below the impeller.

By carefully considering these factors, you can select a suitable mud agitator that performs effectively in practical operations.