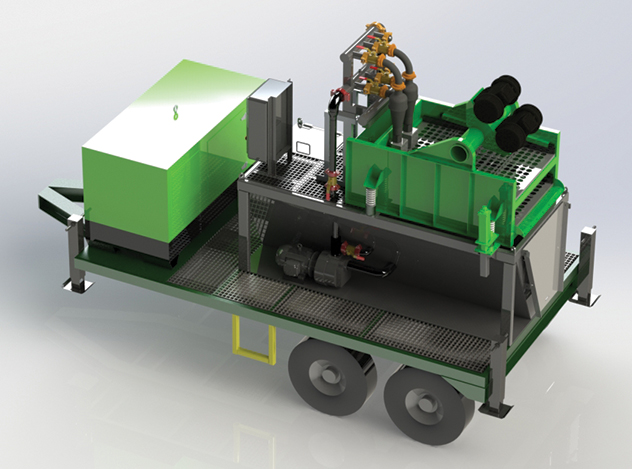

The Kemtron Mud Recycling System is a comprehensive solution that ensures drilling fluids are recycled and reused, which extends their usability and reduces the need for fresh mud. This is particularly important in environments where large amounts of drilling fluid are consumed, and the cost of disposal can be high. The system works by separating solid particles from the mud, allowing the clean fluid to be reused for further drilling operations. This system helps to maintain the required properties of the drilling mud, ensuring efficient cutting removal, lubrication, and cooling.

The Kemtron system is designed with several critical components that work together seamlessly. These include:

- Shale Shakers: The first line of defense in the filtration process. These are used to remove large cuttings from the drilling mud.

- Mud Cleaners: These are used after the shale shakers to further clean the mud by removing finer particles.

- Desanders: These are equipment that help remove larger solid particles.

- Desilters: These further refine the drilling fluid by filtering out smaller solids.

- Centrifuges: For separating fine particles from the mud, increasing the quality of the recycled fluid.

- Transfer Pumps: To move the cleaned mud from one component to another.

How the Kemtron Mud Recycling System Works

The Kemtron Mud Recycling System works in a multi-stage filtration process that improves the quality of the drilling fluid, reduces the need for frequent mud disposal, and ensures optimal drilling performance. Here’s how it works:

- Initial Separation: The drilling fluid, which is contaminated with rock cuttings and other solid particles, enters the shale shaker. The shaker uses vibration to filter out large particles.

- Further Filtration: After the initial separation, the mud moves to the desanders and desilters. These components remove smaller solid particles from the fluid.

- Centrifuge Processing: The cleaned fluid is then processed in a centrifuge, which spins the mud at high speeds to separate even finer particles. This helps to achieve a high-quality, reusable fluid.

- Recycled Fluid: After the centrifuging process, the clean mud is returned to the drilling rig where it is reintroduced into the drilling operation.

The benefits of this system are not only in the immediate recycling of the fluid but also in maintaining the viscosity, density, and lubricating properties of the mud. This is crucial in maintaining the integrity of the wellbore and preventing issues such as stuck pipe or excessive torque during drilling.

Key Benefits of the Kemtron Mud Recycling System

- Cost Efficiency: The recycling of drilling fluids reduces the need for purchasing new mud, lowering operational costs.

- Environmental Sustainability: By reducing waste and ensuring that fewer harmful chemicals are disposed of, the system promotes an environmentally friendly drilling operation.

- Enhanced Performance: The clean, recycled fluid maintains optimal drilling conditions, leading to more efficient drilling and reduced downtime.

- Extended Equipment Life: By filtering out harmful solids, the Kemtron Mud Recycling System reduces wear and tear on other equipment such as pumps and motors.

- Regulatory Compliance: Many drilling operations are subject to strict environmental regulations, and the system helps ensure compliance by minimizing waste and ensuring proper disposal of contaminated mud.

Technical Specifications

The Kemtron Mud Recycling System is customizable based on the specific needs of the drilling operation. Here are some typical specifications:

| Component | Specification |

|---|---|

| Shale Shaker Capacity | Up to 1500 GPM (gallons per minute) |

| Desander Capacity | Up to 1000 GPM |

| Desilter Capacity | Up to 800 GPM |

| Centrifuge Capacity | Up to 200 GPM (for fine solids removal) |

| Mud Tank Size | Customizable based on site needs (typically 500 – 3000 BBL) |

| Power Requirements | 380V/50Hz or 460V/60Hz (depending on location) |

Application Areas of Kemtron Mud Recycling System

The Kemtron Mud Recycling System can be applied across various sectors, including:

- Oil and Gas Drilling: Whether onshore or offshore, the system is invaluable in maintaining drilling efficiency and reducing environmental impact.

- Mining: In mining operations, the system is used to clean the fluids that help in drilling through rock and soil, maintaining a constant supply of clean fluid for operations.

- Geotechnical Drilling: For deep borehole investigations, where continuous and clean fluid is essential to avoid contamination of the samples.

Conclusion

In conclusion, the Kemtron Mud Recycling System plays a vital role in ensuring the efficiency, sustainability, and cost-effectiveness of drilling operations. With its advanced filtration components, including shale shakers, mud cleaners, and centrifuges, the system enables the reuse of drilling fluids, reducing the need for new materials while also minimizing waste disposal. By enhancing the performance of the drilling mud, it supports more effective cutting removal, lubrication, and cooling, contributing to safer and faster drilling operations. Moreover, the system helps companies meet regulatory requirements and enhance their environmental sustainability efforts, making it a crucial part of modern drilling technology.