Screw conveyors are widely used in the oil extraction industry to efficiently transport various materials such as crude oil, sand, water, and other by-products during drilling and extraction processes. Their versatility, reliability, and cost-effectiveness make them ideal for handling materials in challenging environments. In oil extraction operations, screw conveyors provide seamless movement of solids, liquids, and slurries through horizontal or inclined systems. These conveyors offer a solution for transporting heavy, abrasive, and sticky materials while minimizing downtime and maximizing operational efficiency.

Below is a detailed exploration of the role of screw conveyors in the oil extraction industry. This document covers various aspects of their application, maintenance, types, advantages, challenges, and technological advancements in the field.

Table of Contents

- 1. Introduction

- 2. The Role of Screw Conveyors in Oil Extraction

- 3. Types of Screw Conveyors Used in Oil Extraction

- 3.1. Horizontal Screw Conveyors

- 3.2. Inclined Screw Conveyors

- 3.3. Vertical Screw Conveyors

- 4. Advantages of Using Screw Conveyors in Oil Extraction

- 5. Application Areas of Screw Conveyors in Oil Extraction

- 5.1. Transporting Drilling Mud

- 5.2. Oil Sludge Handling

- 5.3. Waste Material Management

- 6. Technical Specifications and Features of Screw Conveyors

- 6.1. Capacity and Speed

- 6.2. Material Compatibility

- 7. Maintenance and Troubleshooting of Screw Conveyors

- 8. Challenges and Limitations of Screw Conveyors in Oil Extraction

- 9. Future Trends and Technological Advancements in Screw Conveyors

- 10. Conclusion

1. Introduction

Screw conveyors are an essential part of the oil extraction process. They provide an efficient and reliable method for moving materials within the production system. These conveyors are designed to handle a wide range of materials in the harsh conditions of the oil field, from transporting heavy slurries to moving lighter by-products. The design flexibility of screw conveyors allows them to be adapted for various tasks, including horizontal, inclined, or vertical material handling. This makes them indispensable in managing the diverse challenges of the oil extraction process.

2. The Role of Screw Conveyors in Oil Extraction

Screw conveyors are commonly used for transporting a wide variety of materials in the oil extraction process. These materials include crude oil, water, drilling mud, sand, and various other waste products. The ability of screw conveyors to handle these materials efficiently helps reduce operational costs and enhance the speed of the extraction process.

In the oil extraction industry, screw conveyors are used in several stages of production, such as during drilling, refining, and waste management. They are particularly valuable in situations where other types of conveyors might struggle due to the materials' abrasiveness, stickiness, or high viscosity.

3. Types of Screw Conveyors Used in Oil Extraction

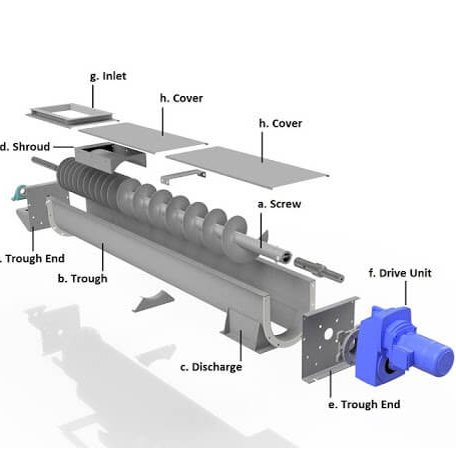

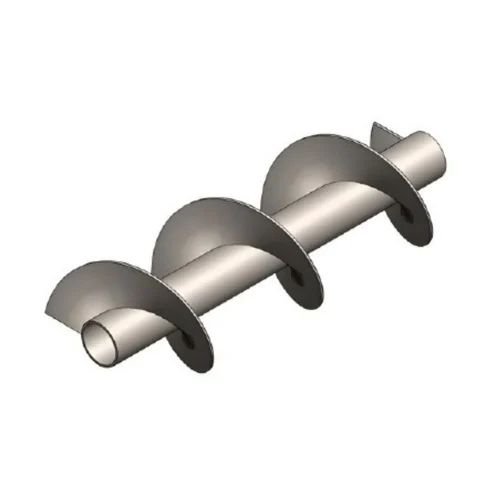

Screw conveyors come in different configurations, each suited for specific applications in the oil extraction industry. The most common types used are horizontal, inclined, and vertical screw conveyors. Each type has distinct advantages depending on the material being transported and the physical layout of the oil extraction site.

3.1. Horizontal Screw Conveyors

Horizontal screw conveyors are the most common type used in the oil extraction industry. They are ideal for transporting materials across long horizontal distances. Their simple design allows them to be easily integrated into various parts of the extraction process, including waste management and crude oil transport. These conveyors are typically used to move dry materials such as sand and sludge, which are prevalent by-products in the extraction process.

3.2. Inclined Screw Conveyors

Inclined screw conveyors are used when there is a need to move materials vertically at an angle. These conveyors are commonly used in situations where space is limited or where materials need to be moved to different levels of the extraction facility. They are particularly useful in handling drilling mud and oil sludge that need to be lifted from one area to another within the system.

3.3. Vertical Screw Conveyors

Vertical screw conveyors are designed to move materials in a vertical direction. These conveyors are ideal for moving materials from the ground level to higher levels within the extraction facility. In the oil extraction industry, vertical screw conveyors are used for handling drilling mud and other waste materials that need to be elevated for processing or disposal.

4. Advantages of Using Screw Conveyors in Oil Extraction

Screw conveyors offer numerous benefits in oil extraction, including increased efficiency, safety, and cost-effectiveness. Below are some of the key advantages of using screw conveyors in the oil extraction process:

- Efficiency: Screw conveyors can transport large quantities of materials quickly and continuously without requiring excessive space or complex machinery.

- Flexibility: They can handle a wide variety of materials, including viscous liquids, heavy solids, and abrasive slurries.

- Minimal Maintenance: Screw conveyors are low-maintenance systems, which helps reduce downtime and operational costs in the extraction process.

- Compact Design: These conveyors take up less space compared to other types of material handling equipment, making them suitable for confined work areas.

5. Application Areas of Screw Conveyors in Oil Extraction

Screw conveyors are used in various stages of the oil extraction process. Some common applications include transporting drilling mud, managing oil sludge, and handling waste materials. Below are some key applications:

5.1. Transporting Drilling Mud

Drilling mud is an essential part of the drilling process, used to lubricate the drill bit and remove cuttings. Screw conveyors are employed to move drilling mud from the drilling site to storage or processing facilities. These conveyors must be designed to handle the high viscosity and abrasiveness of drilling mud, ensuring smooth and continuous transport.

5.2. Oil Sludge Handling

Oil sludge is a by-product of oil extraction that must be managed efficiently to prevent environmental contamination. Screw conveyors play a crucial role in transporting oil sludge from the extraction process to storage or treatment facilities. Their ability to handle heavy, sticky, and abrasive materials makes them ideal for this application.

5.3. Waste Material Management

In addition to drilling mud and oil sludge, screw conveyors are also used to transport various other waste materials produced during oil extraction. These include sand, water, and other by-products that must be disposed of or recycled. Screw conveyors help manage these materials by moving them to designated waste treatment areas, ensuring compliance with environmental regulations.

6. Technical Specifications and Features of Screw Conveyors

When selecting a screw conveyor for oil extraction applications, several technical factors need to be considered, including capacity, speed, material compatibility, and power requirements. These factors influence the performance and efficiency of the conveyor system.

6.1. Capacity and Speed

The capacity and speed of a screw conveyor are critical factors in determining its suitability for specific oil extraction tasks. Higher capacities are required for transporting large quantities of material, while higher speeds are necessary for quicker movement. Below is an example of a typical specification chart for screw conveyors used in oil extraction:

| Conveyor Type | Capacity (tons/hr) | Speed (rpm) | Motor Power (kW) |

|---|---|---|---|

| Horizontal | 10-100 | 50-120 | 1-5 |

| Inclined | 5-50 | 50-100 | 2-8 |

| Vertical | 3-30 | 40-90 | 3-10 |

6.2. Material Compatibility

Screw conveyors must be compatible with the materials being transported in oil extraction. Common materials include crude oil, water, drilling mud, and oil sludge. The conveyor system must be designed to handle the specific characteristics of these materials, such as their viscosity, abrasiveness, and potential for clogging. Specialized screw conveyors with corrosion-resistant materials and wear-resistant components are often used for handling challenging materials.

7. Maintenance and Troubleshooting of Screw Conveyors

Regular maintenance is essential for ensuring the longevity and efficient performance of screw conveyors in oil extraction. Proper lubrication, alignment, and cleaning are necessary to prevent wear and tear. Troubleshooting should focus on detecting issues like power failure, material clogging, or belt misalignment.

8. Challenges and Limitations of Screw Conveyors in Oil Extraction

While screw conveyors are highly effective in many oil extraction applications, they do have limitations. These include their inability to handle extremely high-viscosity materials or materials that are prone to solidifying. Additionally, screw conveyors may face issues with clogging and wear when handling abrasive substances.

9. Future Trends and Technological Advancements in Screw Conveyors

The future of screw conveyors in oil extraction lies in advancements such as improved energy efficiency, better material handling capabilities, and the integration of smart technologies for real-time monitoring and performance optimization.

10. Conclusion

Screw conveyors continue to be an indispensable part of oil extraction, offering reliable, efficient, and cost-effective solutions for material handling. Their versatility, combined with technological advancements, ensures that they will remain crucial in the future of the oil extraction industry.